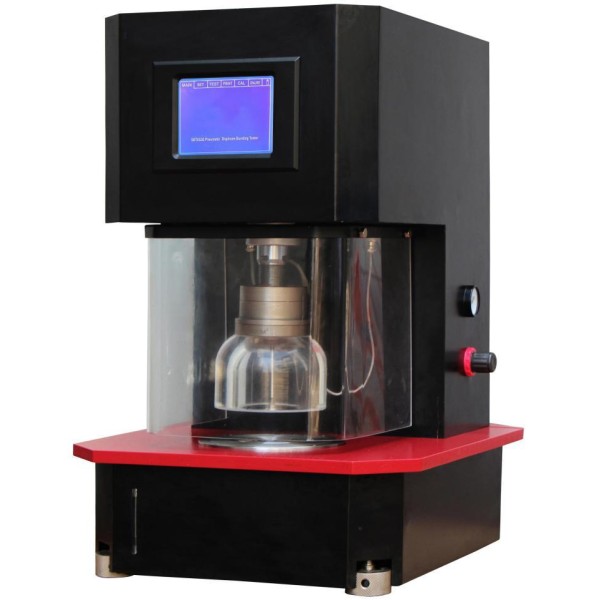

Hydraulic Bursting Tester

- Product Code: HD-W813

Application:

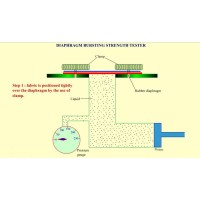

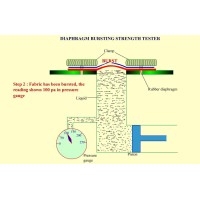

Textile fabrics having no particular directions cannot be tested its

strength via tensile testers; a multi-directional force generated by

hydrostatic pressure is applied on fabric to check the strength of that fabric,

this phenomenon is called bursting strength testing. Automatic Hydraulic

Diaphram Bursting Tester is specially designed to perform the bursting strength

testing of knitted fabrics, with pneumatic control. It can also be used for

leather, paper & card Boards, etc.

To determine the bursting strength and distension at the burst of woven and

knitted fabrics as well as technical textiles,non-wovens, bonded

fabrics, plastics, leather (artificial and natural), and cardboard.

Standards:

ASTM D4966, D 4970, D 3866

ISO 12945-2, ISO 12947.1

ASTM D 3786 Standard Test Method for Hydraulic Bursting Strength of

Textile Fabrics Diaphragm Bursting Strength Tester Method

BS 4768 Determination of Bursting Strength and Bursting Distension

ISO 13938-1 Textile - Bursting properties of fabrics, Hydraulic method

for determination of bursting strength and bursting distension

ISO 2758 Paper - Determination of bursting strength

ISO 2759 Board - Determination of bursting strength

ISO 3303 Rubber - or plastics-coated fabrics - Determination of bursting

strength - Hydraulic method

WSP 030.1.R3(12),BS 3424(PT6),ERT 80-4-20,EN 12332-2,IWS TM 29,ASTM

D751, JIS L-1018

Features:

- This burst test equipment uses a hydraulic method, meet multinational standards, and equipped with several changeable

test clamp.

- The simple interface

touching a screen controller is easy and simple to handle.

- The specimen was clamped firmly by the pneumatic force which can also save effort.

- The burst

test cover was made up of high-transparent glass with LED light inside which can observe the specimen easily.

- The burst test equipment can induct the burst automatically which is much more sensitive and reliable.

- The bursting distension can go up to 75mm.

- The AC servo drive system

with low noise and a wide range of applications.

- 4 Test Methods: Constant

Rate Bursting, Constant Expansion, Constant Pressure, and Constant Time

Bursting.

- The burst

tester bring saving and printing functions and support on-line

operation.

- Provide on-line

interfaces, professional detection software which can be used to analysis

testing result.

| Technical Specification: | |

| Item | Parameter |

| Areas of Application | Textiles: Knitted and woven apparel. Technical textiles |

| Nonwovens: Wet wipes, surgical gowns/masks | |

| Plastics: Food packaging, bin liners, sacks, and various plastic products | |

| MedicakOrgan patches, hernia patches, wound dressings, animal skin | |

| Paper: Kitchen paper. Toilet tissue. Other paper products | |

| Pressure measurement range | 2000kPa, L/C: 1kPa |

| Distension measurement range | Up to 75 ± 0.02 mm |

| Measuring areas | 7.55cm2 (Ø 31mm) and 50cm2 (Ø 79.8mm) |

| Unit of measurement | kPa - kg/cm2 - mmHg - lb/in2 - atm |

| Test methods | Constant Rate - Constant Pressure - Constant Distension -Timing |

| Hydraulic system rate of flow (adjustable) | 20-600mL/min |

| Hydraulic oil | Glycerine 85%, distilled water 15% |

| Safety sensor | Over scale auto-stop |

| Diaphragm rubber thick | < 2 mm |

| Data port | RS232 port for printer connection and 3 pin Mini-DIN connector for PC |

| Dimensions | 550 x 450 x 700 mm |

| Power supply | 220V,50Hz |

| Air requirements | 600-800kPa |

| Weight | 125kg |

| STANDARD | TEST HEAD SELECTION | ||||

| 30.5 mm | 31 mm | 31.5 mm | 35.7 mm | 79.8 mm | |

| (7.3 cm2) | (7.55 cm2) | (7.8 cm2) | (10 cm2) | (50 cm2) | |

| ASTM D3786 | * | ||||

| BS 3424-6-B | * | * | * | ||

| EN 12332-2 | * | ||||

| ERT 80-4-20 | * | ||||

| FZHT01030 | * | ||||

| IS013938-1 | * | * | * | ||

| ISO 3303-8 | * | ||||

| GB/T 77411 | * | ||||

| W5P 030.1R3(12) | * | * | |||

| WSP Q30JLR3 (12) | * | * | * | ||

| Distension Height | 39 mm | 39 mm | 39 mm | 39 mm | 70 mm |

| This list of standards is a partial listing of the most common textile standards. The instrument can also be used for packaging, paper, plastic, and foil. | |||||

| Standard Configuration: | ||

| No. | Item | Quantity |

| 1 | Main Unit | 01 No. |

| 2 | Test Kit 7.55cm2 (0 31mm) and 50cm2 (0 79.8mm) | 01 No.(each) |

| 3 | Synthetic Rubber Diaphragms | 02 Nos. |

| 4 | Diaphragm Unit Tightening wrench | 01 No. |

| 5 | Air Pipe (To connect with compressor) | 01 No. |

| 6 | Glycerol (500mL) | 01 No. |

| 7 | USB software | 01 No. |

| 8 | Power Cord | 01 No. |

| 9 | This User s Manual | 01 No. |

| 10 | Inspection &. Conformance Certificate | 01 No. |